AC drive for belt conveyor

Belt conveyor introductionUtilizing of multi-drive belt conveyor is widely used in the mining transportation system.

During the starting process, if the soft start equipment is not applied, the belt conveyor will be damaged easily due to the big tension vibration. In another hand, if we start the motor directly, the start current will be 4~7times of the motor rating current, this big surge current will change the internal mechanical stress and thermal stress of motor, and cause serious abrasion and damage to the mechanical part. Meanwhile, the big surge current will cause big voltage drop of the grid, and effect other equipment’s operation.

AC drive solution introduction

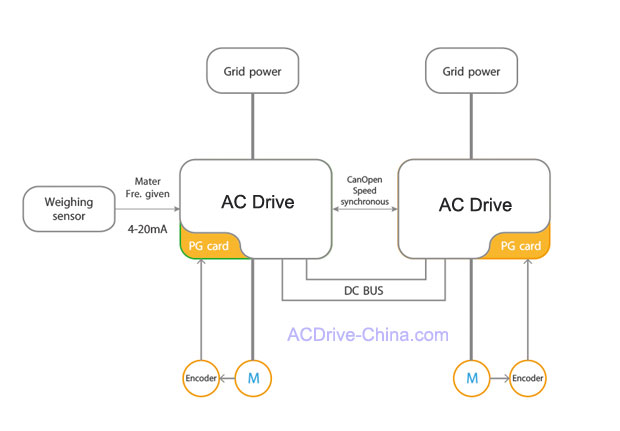

The AC drive controlled system consists of two drives, weight sensor, PG card, encoder etc. Normally, it needs to upgrade the both terminals’ motors, the system diagram is shown as below.

(1)The two AC drives are common DC bus connected, the regenerated energy can be reused internally.

(2)One VFD drive set as master, another one set as slave, because the belt conveyor is flexible connection, the master-slave motors can be controlled by speed.

(3)The master drive receives the 4-20mA signal from weight sensor to calculate its output frequency, this frequency signal will output to slave AC drive as it frequency reference, to achieve the synchronous speed and balanced power of the two motors.

(4)Both of the master and slave system are close-loop vector control mode, to get significant starting torque.

(5)The braking unit of energy feedback unit is necessary for down-running belt conveyor.

Advantage of AC drive in belt conveyor

(1)Good performance of master-slave speed synchronization, realized the master-slave power balance, and the difference of the running current is very less.

(2)It reduces the surge current during start process and also reduces the motor thermal loss while start the motor frequently, prolongs the working lifetime of motor.

(3)The belt conveyor can work at 120% load without failure.

(4)The optimized S curve of the AC drive makes the start and stop of belt conveyor smoother.

(5)Energy saving: In normal condition, the mining motors’ power rating are enlarged too much to ensure the safety operation, but they don’t work at full load in most of the time, and it will cause huge electric loss while in light load or without load. After using of the variable frequency drive in the system, the speed of the belt can be adjusted automatically as the change of the load. In addition, the hydraulic coupler will be removed and the gear-box will be connected with motor directly, it improves the transmission efficiency effectively.