Current vector AC drive for centrifugal dehydrator

Application Technical Requirements:1. The centrifugal dehydrator produces the centrifugal force through high speed rotation to remove water of materials in the stainless steel cylinder. It is widely used for textile, printing, ceramics, chemical industry, mine, hotel, and etc.

2. Centrifugal dehydrator is a typical low damp big inertia load, it must overcome the over-current during start acceleration, and over-voltage during deceleration.

3. Accelerating and decelerating at the maximum rated current of motor, no skipping in normal situations.

4. Big torque at low frequency, powerful start, and stop without coasting.

AC Drive System Configurations

1. Open loop vector control AC drive

2. Current vector control feature

3. Choose braking resistor according the motor power

4. Braking unit is required if the power is more than 15kW

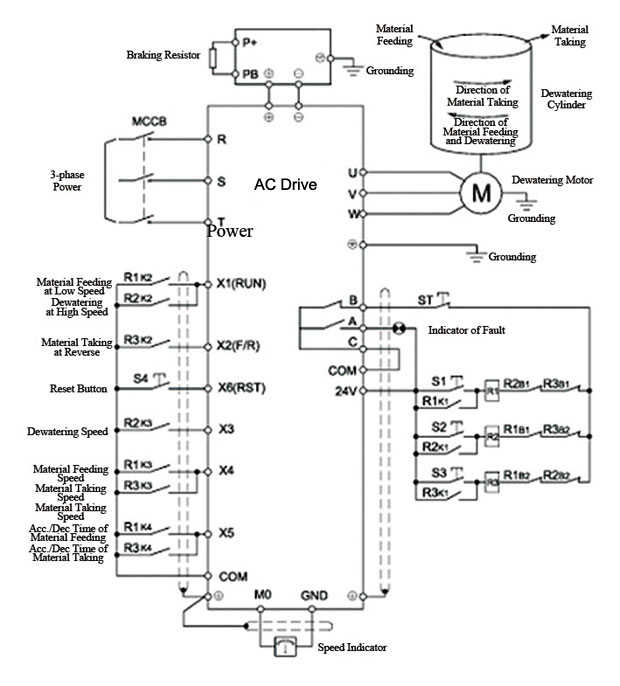

Electric Schematic Diagram of AC drive system

AC Drive System Features:

1. Simple control program on equipment, and easy for commissioning, operation and maintenance.

2. Open loop vector control drive, 150% rated torque output at 1.0Hz. High torque control at low frequency, with stable starting and braking.

3. Current clipping control function is in closed loop mode which is reliable and efficient. Accelerating and decelerating at rated current, no skipping protection. The acceleration/deceleration time automatically prolongs or reduces according to the quality of material in the cylinder.

4. Reliable and efficient DC braking torque, cylinder stops stably without gliding in setting time.

5. No skipping over-current and over-voltage protection at tracking start and stop when the cylinder is gliding.

6. Automatic stop against grid blackout: transfer the big inertia into electricity, then feed back to the AC drive and consumed by the braking resistor by means of heat, avoid causing dehydrator free-stop when supply grid is blackout.