Variable frequency AC drive for air compressor

Air compressor introductionAir compressor is a kind of equipment that uses a motor to compress air in the compressing chamber and brings the compressed air to a certain pressure. As a basic industrial equipment, the air compressor has been widely used in almost all industrial fields such as metallurgy, machine manufacturing, mine, electric power, textile, petrochemical, light textile, etc. The electric energy consumption of air compressors accounts for 15% of all large scale industrial equipments (fan, pump, boiler, air compressor, etc.). Most air compressors have obvious inherent technical weaknesses due to their structure and principle. When the output pressure exceeds a certain value, it automatically opens the relief valve and idles the asynchronous motor. This seriously wastes energy. Moreover, the asynchronous motor tends to start and stop frequently. This affects the service life of the motor. The compressor has high starting current in power frequency mode. This has a high impact on the power grid and causes serious wear of the motor shaft and high maintenance of equipment. The working conditions are harsh and the noise level is high. The automation level is low. The adjustment of output pressure is realized by manually regulating the valve opening. This has the disadvantages of low regulation speed, large fluctuation, low stability and low accuracy.

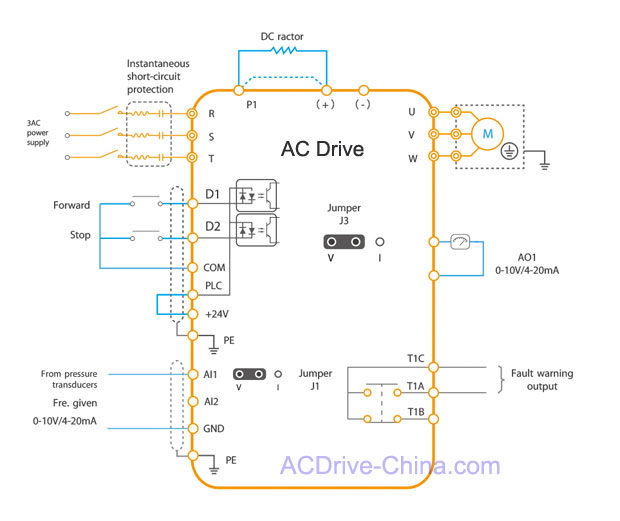

Variable frequency AC drive system

The electric system is consist of variable frequency drive, pressure sensor and other peripheral devices.

(1) The VFD drive adopts sensorless vector control technology to meet the requirement of high torque when low frequency;

(2) The system adopts PID control, please check the whole control process as follow: Air requirement↑ —— Pipe air compress↓—— The difference between pressure setting value and pressure feedback value↑ —— PID output↑ —— AC drive output frequency↑ —— Air compressor motor speed↑ —— Supply air flow↑—— Pipe air compress to stabilize;

(3) 0~10V (or 4~20mA) signal provided by pressure sensor is used as PID given, input AI from the variable frequency drive analog input;

(4) Start, stop signal is given by central control system, the frequency drive can provide analog output signal via AO, then connect to the central control system to monitor pressure fluctuation. Meantime, fault warming signal can be provided by reactor;

(5) You can configure power frequency by-pass to ensure the continuity of production;

Advantage of the VFD drive solution

(1) Active power electricity saving, when air compressor speed reduces, active power electricity saving is more obvious. (The meaning of active power electricity saving is saving energy & lower production cost);

(2) Increase grid side power factor & reactive power electricity saving, the meaning of reactive power electricity saving is that lower the line consumption of workshop power supply bus & the second current of workshop distribution transformer. Meanwhile, reduce of reactive power electricity saving can lower the temperature rise of power transformer to prolong the service life of power transformer;

(3) Stable high load start. Low frequency response of the variable frequency inverter is good, plus big power margin, can totally meet torque requirement when low frequency. So it is definitely suitable for "high load start";

(4) Prolong mechanical life. Lower air compressor speed, reduce air compressor wear, can prolong the service life of air compressor. Meanwhile, the leakage of air compressor oil way is greatly reduced, relieve the pressure of environmental pollution;

(5) Lower oil temperature increase is a good solution for the shortage of air compressor working pressure decreases under high temperature environment;

(6) Reduce noise. Can prove the working environment obviously to provide a good solution for managing the environment noise pollution in professional health governance;

(7) Excellent soft start, soft stop features. The start & stop time of the ac drive inverter can be adjusted randomly (0~10min), means that acceleration when start & deceleration when stop can be adjusted randomly, meanwhile, you can match with S curve ACC/DEC time to start smoothly, which can minimum the impact of air compressor caused by start & stop, this can hardly achieved by other drive devices.